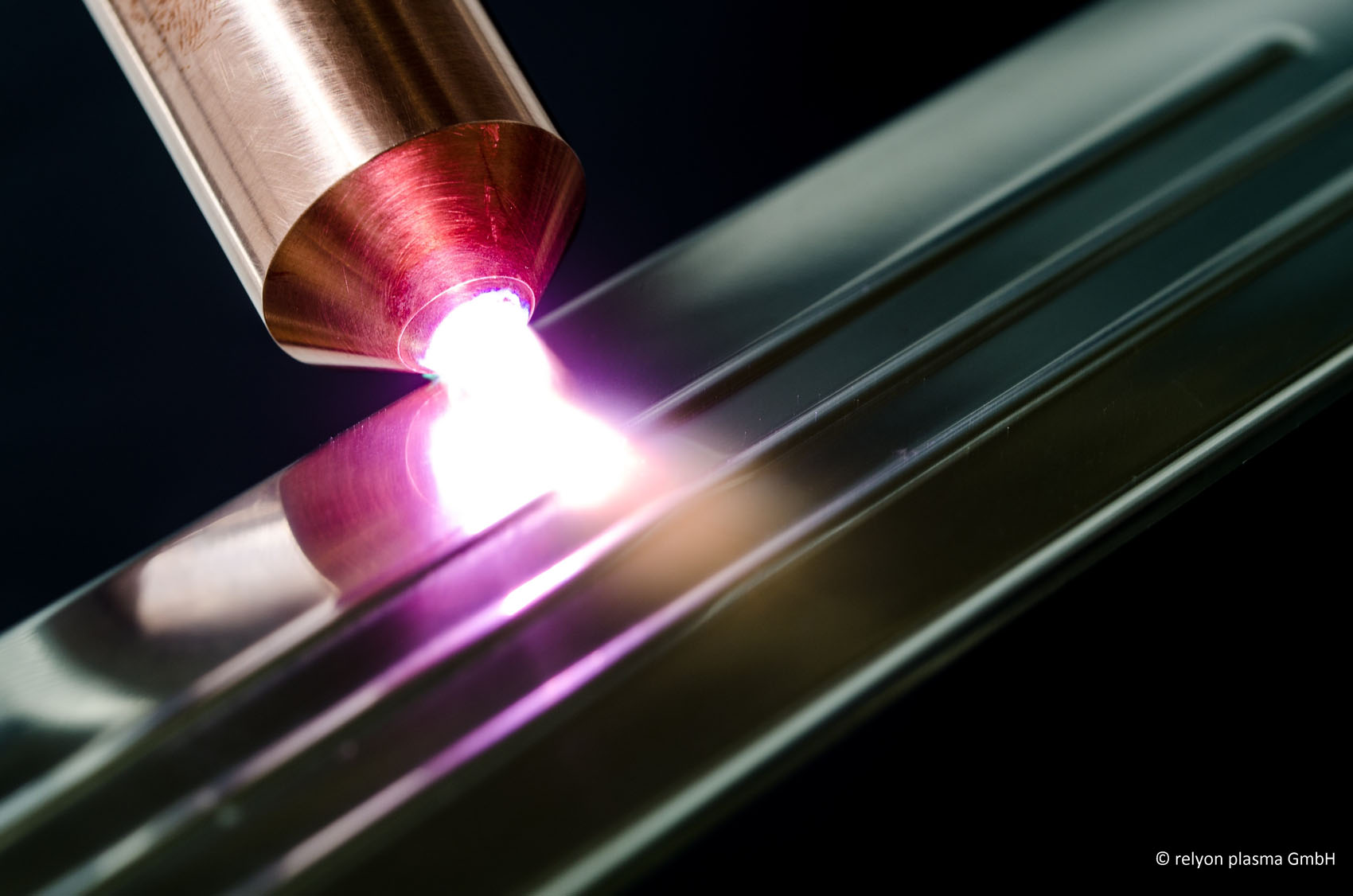

Relyon meets all your configuration needs

Relyon Plasma has decades of experience in the development and implementation of specialized atmospheric plasma systems for manual applications and inline processes. Modular in construction – for manual, stationary and inline solutions.

Relyon plasma technology products are made for in-line capability for industry, business, the skilled trades, research, development, laboratories and medical technology.

Relyon technical platforms can provide you with a comprehensive modular system to suit your requirements. Here, we are able to meet all your configuration needs – from an individual manual work station right through to a fully automated high speed system.

Piezobrush® PZ3

Piezobrush® PZ3 has been designed as a compact plasma handheld device for use in laboratories, predevelopment and assembly of small series. With a maximum power consumption of 18 W, the Piezoelectric Direct Discharge (PDD®) technology is used to generate cold active plasma at a temperature of less than 50°C. The heart of this portable plasma device is the TDK piezo plasma generator CeraPlas™ – a high-voltage discharge device for generating cold atmospheric-pressure plasma. Plasma is used to increase the surface energy of many materials with high efficiency, as well as to reduce germs and odors.

- Activation and functionalization of surfaces of various materials

- Improvement of wettability

- Optimization of bonding, painting, printing and coating processes

- Surface treatment of plastics, glass, ceramics, metals, semiconductors, natural fibres and composite materials

- Ultra-fine cleaning and odour reduction

Piezobrush® PZ2

The piezobrush® PZ2 has been conceived to be an efficient handheld unit. The plasma handheld device is also very suitable for being used in professional model making, in laboratories and the manual assembly of small lots. Bonding of synthetic materials becomes easier due to surface activation resulting from the impact of cold plasma.

Also the adhesion of coatings in the automotive field of application or on polypropylene is optimized. As a further advantage, prior treatment with the piezobrush® handheld unit increases the bonding strength in the case of epoxy-based adhesives being used for bonding materials, such as glass, GRP, ABS and other synthetic materials. Due to the low thermal stress, treatment of materials conventionally used in model making – such as wood and various kinds of paper – using all-purpose power glue is excellent.

At a maximum power consumption of 30W, cold active plasma with a temperature of ~ 50°C is generated. The piezobrush® stands out due to its low-maintenance construction principle. All individual components are characterized by their long-term durability and do not need to be replaced or maintained.

Please don’t hesitate to contact our sales team. We will help you to find the right solutions for your purposes.

Timo Torvikoski

Product Manager

Dispensing, chemicals and raw cables

timo.torvikoski@elgood.fi

tel. +358 (0)40 8372 002